rockwell hardness test pdf download|hardness test lab report pdf : specialty store This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic . WEBJá consolidada como importante destino turístico no País, a cidade de Caldas Novas ganhou recentemente uma atração muito especial: o Kawana Park, mega parque aquático com mais de 38 mil m² e repleto de atrações inéditas na região, com brinquedos radicais e piscinas para todas as idades. Publicidade. Com 75% do parque em funcionamento .

{plog:ftitle_list}

HistóriaO basquete feminino foi introduzido no clube na década de 30. O Palmeiras foi quatro vezes. Ver mais

1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types .

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic .This document specifies the method for Rockwell regular and Rockwell superficial hardness tests for scales A, B, C, D, E, F, G, H, K, 15N, 30N, 45N, 15T, 30T, and 45T for metallic materials .

10.1520/E0018-20. 2 In this test method, the term Rockwell refers to an internationally recognized type of indentation hardness test as defined in Section 3, and not .Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters 1 Scope This part of ISO 6508 specifies two separate methods of . NISTRecommendedPracticeGuide SpecialPublication960-5 RockwellHardness Measurementof MetallicMaterials U.S.DepartmentofCommerce DonaldL.Evans,Secretary . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .

EXAMPLE 70 HR30N = Rockwell superficial hardness of 70 measured on the 30 N scale with a total test force of 294,2 N. 4.4 The Rockwell superficial hardness for the T scale is denoted by the symbol HR preceded by the hardness

Download file PDF Read file. Download file PDF. Read file. Download citation. Copy link Link copied. . • The obtained results for the Rockwell hardness test often deviate from the standard s . Rockwell hardness test - Download as a PDF or view online for free. . AI-enhanced description. yash patel Follow. The Rockwell hardness test was invented in 1914 by Hugh and Stanley Rockwell. It measures the .obtained from computer-generated curves of actual test data. Most Rockwell hardness numbers are presented to the nearest 0.1 or 0.5 hardness number to permit accurate reproduction of these curves. Since all converted hardness values must be considered approximate, however, all converted Rockwell .

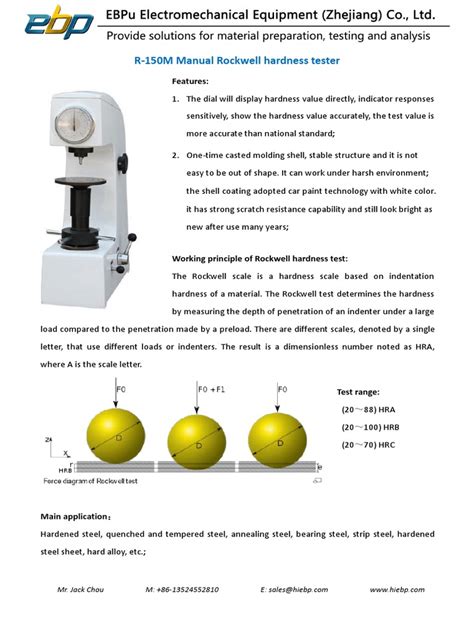

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficialISO 3738-1, Hardmetals — Rockwell hardness test (scale A) — Part 1: Test method [2] ISO 4498, Sintered metal materials, excluding hardmetals — Determination of apparent hardness and microhardness [3] ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995) [4]additional test force (permanent indentation depth) mm HRA HRC HRD Rockwell regular hardness =100 0 002 − h, HRBW HREW HRFW HRGW HRHW HRKW Rockwell regular hardness =130 0 002 − h, HRN HRTW Rockwell superficial hardness =100 0 001 − h, 5 Rockwell hardness 5.1 The following is an example of the designation of Rockwell .Total test force Hardness range applicable Rockwell Superficial hardness 15N HR15N Conical diamond 29.42N (3kgf) Coverage 147.1N (15kgf) 70-94HR15N 30N HR30N 294.2N (30kgf) 42-86HR30N 45N HR45N 441.3N (45kgf) 20-77HR45N 15T HR15T Sphere ø1.5875mm (1/16") 147.1N (15kgf) 67-93HR15T

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .4.3 Verification of the indenter 4.3.1 Diamond cone indenter (scales A, C, D, N) To verify the reliable performance of the conical indenter in conformance with this part of ISO 6508, a direct5.1.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98

visual motor speed composite impact test

See full PDF download Download PDF. Related papers. Bogazici University Materials Science Course - Hardness Tests Lab Report. Deniz Akyazı. This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness test. Its main goal is understanding the concept of hardness and . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.1.5 Units - At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the .In Rockwell hardness test, a standard load (based on type of material) is applied through a standard indentor (cone or ball) for a specified duration, on the material & depth of impression / indentation is directly measured and read as hardness number on a dial gauge. Rockwell Hardness Tester. Equipments: 1. Rockwell hardness tester. 2.

E 140 Hardness Conversion Tables for Metals (Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell Superficial Hardness, Knoop Hard-ness, and Scleroscope Hardness)3 E 384 Test Method for Microindentation Hardness of Ma-terials3 3. Terminology 3.1 calibration—determination of the values of the signifi-Metallic materials — Rockwell hardness test — Part 1: Test method. Edition 4 2016-08. Withdrawn. ISO 6508-1:2016. 70460. ISO 6508-1:2016 Metallic materials — Rockwell hardness test Part 1: Test method. Withdrawn (Edition 4, 2016) .3.1 Macro Hardness Test Methods 3.1.1 Rockwell Hardness Test The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load 𝐹0 (Fig. 1A) usually 10 kgf. When equilibrium has been reached, an

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load. Download file PDF Read file. Download file PDF. Read file. Download citation. Copy link Link copied. . Rockwell hardness test, the preliminary test force is 10 kgf (98. N) and the total test .

Rockwell Hardness Test - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. The Rockwell hardness test measures the hardness of a material by applying two loads to a diamond or steel ball indenter that is pressed into the surface of the material. The hardness number is determined using the . In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.Rockwell hardness test is to apply diamond cone indenter (see Fig-2) or steel ball indenter (see Fig-3) to the specimen surface in two steps as shown in Fig-1, which shall be retained for a certain period of time, and measure the residual indentation depth under preliminary test force after the main test force is removed. The Rockwell hardness isSee full PDF download Download PDF. Related papers. . Rockwell hardness test (d) Rebound hardness test (e) Scratch test In the experiment, Brinell hardness test was used in attempt to examine the relation of the deformation of metal specimen to the hardness property of a metal. Using a hardened steel ball fixed unto a Brinell Hardness Test .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

rockwell hardness testing procedure pdf

Galaga is a fixed shooter arcade game developed and published by Namco in Japan and published by Midway in North America in 1981. It is the sequel to Galaxian, released in 1979. The gameplay of Galaga puts the player .

rockwell hardness test pdf download|hardness test lab report pdf